In 2001 Toyota, the Japanese car manufacturer set out the principles of how people, within their organization should behave. These principles of corporate culture were made popular inn 2004 by, Dr. Jeffrey Liker, a University of Michigan professor of industrial engineering, in his book The Toyota Way.

The principles based on continuous improvement, Kaizen, and respect for people have been applied to many different fields including sports, healthcare, psychotherapy, life coaching, government and banking.

Notably, Team Sky, the British cycling team from 2010–2019 under David Brailsford and Chris Boardman used these principles (even down to carrying the cyclist favourite pillows for sleeping) to take the team to domination of cycling. By improving every possible aspect even by 1%, across everything, they were able to win most of the major competitions world-wide.

In fact, the system of continuous incremental improvement by small steps is applicable to most things including habit change, personal progress and finding meaning and purpose in occupations.

The Toyota Way is a system designed to provide the tools for people to continually improve their work. According to Liker, the 14 principles of The Toyota Way are organized in four sections:

1. Long-term philosophy

2. The right process will produce the right results

3. Add value to the organization by developing your people,

4. Continuously solving root problems drives organizational learning.

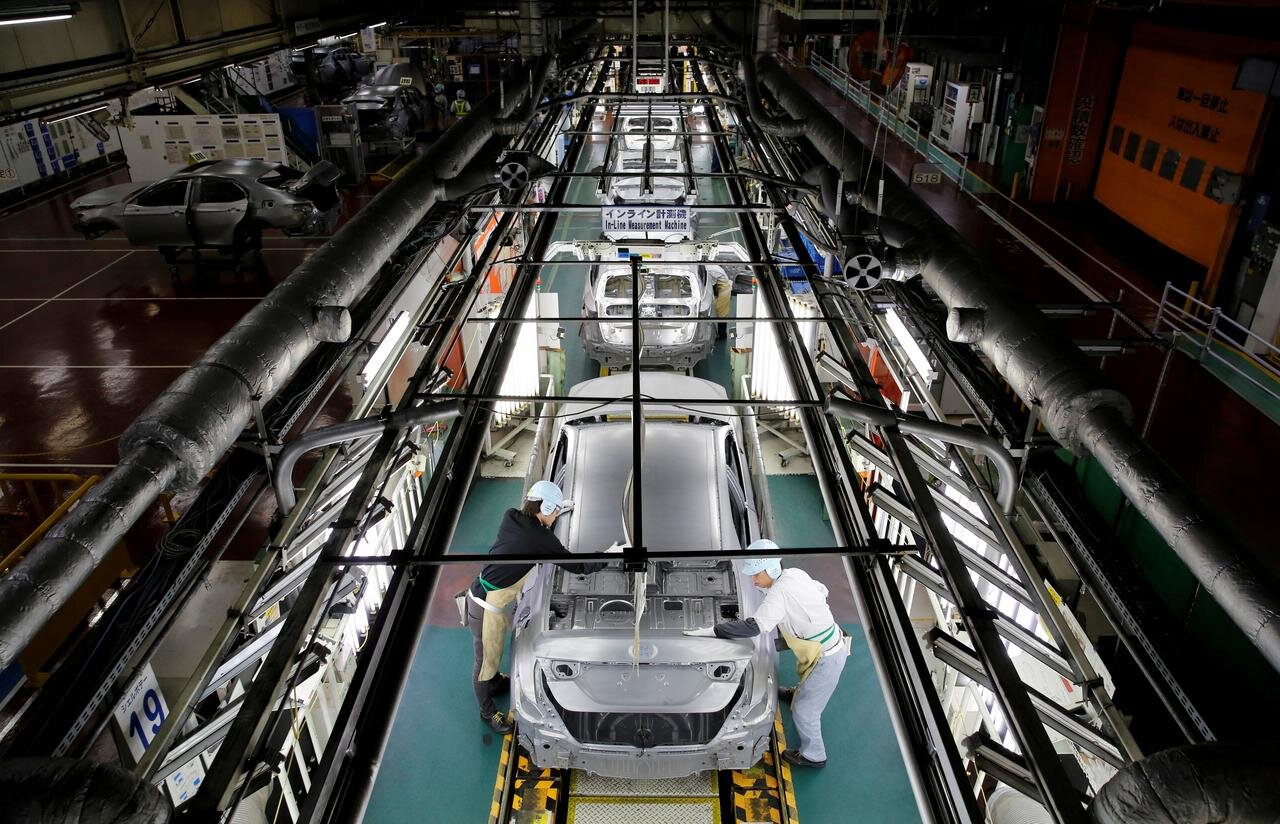

Toyota Factory

The principles for a continuous improvement include establishing a long-term vision, working on challenges, continual innovation, and going to the source of the issue or problem. The principles relating to respect for people include ways of building respect and teamwork.

The 14 Principles

Section 1 — Long-Term Philosophy

Principle 1

· Base your decisions on a long-term philosophy, even at the expense of short-term goals.

People need purpose to find motivation and establish goals.

Section II — The Right Process Will Produce the Right Results.

Principle 2

· Create a continuous process flow to bring problems to the surface.

Work processes are redesigned to eliminate waste through the process of continuous improvement, Kaizen. The seven types of waste are:

1. Overproduction

2. Waiting (time on hand)

3. Unnecessary transport or conveyance

4. Over-processing or incorrect processing

5. Excess inventory

6. Motion

7. Defects

Principle 3

· Use "pull" systems to avoid overproduction.

A method where a process signals its predecessor that more material is needed. The pull system produces only the required material after the subsequent operation signals a need for it. This process is necessary to reduce overproduction.

Principle 4

· Level out the workload. (Work like the tortoise, not the hare).

This helps achieve the goal of minimizing waste, not overburdening people or the equipment, and not creating uneven production levels.

Principle 5

· Build a culture of stopping to fix problems, to get quality right the first time.

Quality takes precedence. Any employee in the Toyota production system has the authority to stop the process to signal a quality issue.

Principle 6

· Standardized tasks and processes are the foundation for continuous improvement and employee empowerment.

Although Toyota has a bureaucratic system, the way that it is implemented allows for continuous improvement (kaizen) from the people affected by that system. It empowers the employee to aid in the growth and improvement of the company.

Principle 7

· Use visual control so no problems are hidden.

Included in this principle is the 5S Program - steps that are used to make all work spaces efficient and productive, help people share work stations, reduce time looking for needed tools and improve the work environment.

Sort: Sort out unneeded items

Straighten: Have a place for everything

Shine: Keep the area clean

Standardize: Create rules and standard operating procedures

Sustain: Maintain the system and continue to improve it

Principle 8

· Use only reliable, thoroughly tested technology that serves your people and processes.

Technology is pulled by manufacturing, not pushed to manufacturing.

Section III — Add Value to the Organization by Developing Your People

Principle 9

· Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others.

Without constant attention, the principles will fade. The principles have to be ingrained; it must be the way one thinks. Employees must be educated and trained: they have to maintain a learning organization.

Principle 10

· Develop exceptional people and teams who follow your company's philosophy.

Teams should consist of 4-5 people and numerous management tiers. Success is based on the team, not the individual.

Principle 11

· Respect your extended network of partners and suppliers by challenging them and helping them improve.

Toyota treats suppliers much like they treat their employees, challenging them to do better and helping them to achieve it.

Section IV — Continuously Solving Root Problems Drives Organizational Learning

Principle 12

· Go and see for yourself to thoroughly understand the situation.

Toyota managers are expected to "go-and-see" operations. Without experiencing the situation firsthand, managers will not have an understanding of how it can be improved. Always keep the final target in mind.

1. Clearly assign tasks to yourself and others.

2. Think and speak on verified, proven information and data.

3. Take full advantage of the wisdom and experiences of others to send, gather or discuss information.

4. Share information with others in a timely fashion.

5. Always report, inform and consult in a timely manner.

6. Analyze and understand shortcomings in your capabilities in a measurable way.

7. Relentlessly strive to conduct Kaizen activities.

8. Think "outside the box," or beyond common sense and standard rules.

9. Always be mindful of protecting your safety and health.

Principle 13

· Make decisions slowly by consensus, thoroughly considering all options; implement decisions rapidly.

The following are decision parameters:

1. Find what is really going on (go-and-see) to test

2. Determine the underlying cause

3. Consider a broad range of alternatives

4. Build consensus on the resolution

5. Use efficient communication tools

Principle 14

· Become a learning organization through relentless reflection and continuous improvement.

The process of becoming a learning organization involves criticizing every aspect of what one does. The general problem-solving technique to determine the root cause of a problem includes:

1. Initial problem perception

2. Clarify the problem

3. Locate area/point of cause

4. Investigate the root cause (5 Whys)

5. Countermeasure

6. Evaluate

7. Standardize

The final principle requires that Toyota be a "learning organization", continually reflecting on its practices and striving for improvement. According to Liker, the process of becoming a learning organization involves criticizing every aspect of what one does.

Kaizen Principle

Long-term philosophy

The first principle involves managing with a long-view rather than for short-term gain. This reflects the belief that people need purpose to find motivation and establish goals. People find purpose by establishing a personal meaning by being invested into the outcome of a project in the belief that they have some influence or control of the outcome. Finding meaning and therefore purpose better enables people to feel invested and motivated.

Right process will produce right results

Everything is focused on the quality of the outcome. Following these principles, work processes are redesigned to eliminate waste through the process of continuous improvement - Kaizen. The seven types of waste identified are (1) overproduction; (2) waiting, time on hand; (3) unnecessary transport or conveyance; (4) over processing or incorrect processing; (5) excess inventory; (6) motion; and (7) defects.

The idea is to empower the employee or the team by enabling anyone involved the power to stop the process for a quality issue. This is also seen as a method of implementing continuous improvement. This also allows team members to feel that their input is valuable and consequential.

Value to organization by developing people

Human development is the focus and emphasizes the need to ensure that leaders embrace and promote the corporate philosophy. This reflects, according to Liker, a belief that the principles have to be ingrained in employees to survive. The emphasis is on individuals working in small teams. This attitude should extend out to the whole supply chain and customers too.

Solving root problems drives organizational learning

The final principles embrace a philosophy of problem solving that emphasizes thorough understanding, consensus-based solutions, swiftly implemented and continual reflection and improvement, encouraging thorough consideration of possible solutions through a consensus process, with rapid implementation of decisions once reached.

The final principle requires that the organization or team should be a "learning organization", continually reflecting on its practices and striving for improvement.

Becoming a learning organization involves constructive criticism every aspect of what one does.

Sources:

Mindtools.com https://www.mindtools.com/pages/article/newSTR_97.htm

wikipedia.com https://en.wikipedia.org/wiki/Kaizen#Overview

Wikipedia.com https://en.wikipedia.org/wiki/The_Toyota_Way

Maurer, Robert (2012). The Spirit of Kaizen: Creating Lasting Excellence One Small Step at a Time (1 ed.). McGraw-Hill.

Bodek, Norman (2010). How to do Kaizen: A new path to innovation - Empowering everyone to be a problem solver.